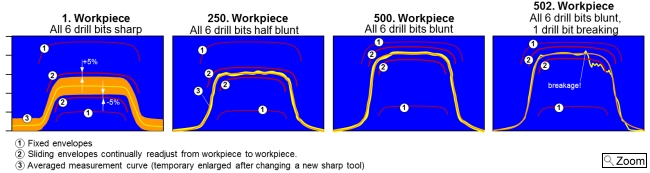

Sliding Envelope Adjustment

Scopes of Application of the Sliding Envelope

- Drill bit breakage detection in multi-spindle drill heads via effective power measurement

- Monitoring from the first workpiece with an initially rough limit distance which successively decreases from workpiece to workpiece (in combination with the "averaged curve")

- Turning with great allowance deviations (Recalculation of the envelope at each workpiece rotation based on the measurement curve of the previous rotation)

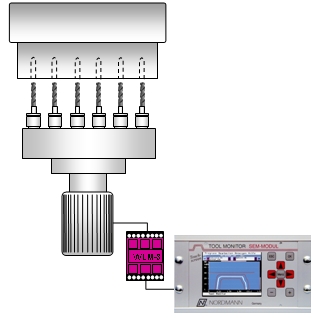

Application example multi-spindle drill head:

Application example multi-spindle drill head:

Allows for breakage monitoring of several drill bits driven by a common motor via effective power measurement.

Original problem: Changes in measured value height due to the breakage of a single drill bit are smaller than changes due to the wear of all drill bits. Thus, fixed envelops are not violated.

Solution: Sliding adjustment of the envelope limits from workpiece to workpiece to the changes in measurement curve height due to tool wear. This allows for a much smaller distance between envelope and measurement curve.

The envelope follows, at a percentage distance (e.g. ± 5 %), an "averaged measurement curve" obtained by averaging across the last workpieces.